Scott Gardiner, KWM’s Co-Global Head of Projects, Energy and Resources, and Tiffany Kwong deliver their latest fun fact on hydrogen. Turning to the popular fertiliser, ammonia, they ask – will it fuel ships of the future (among other energy carrier uses)?

We are back with another fun fact for anyone else with the same insatiable interest in clean fuel and a carbon zero future.

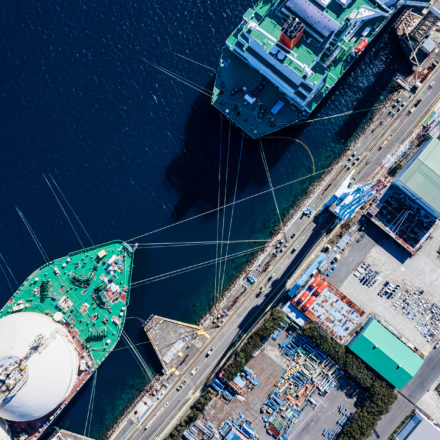

We previously talked about the first large-scale shipment of liquid hydrogen thanks to Suiso Frontier (do you recall what ‘Suiso’ means in Japanese? Hint: it tops the periodic table and produces fun facts). As much as this carries hope, it also highlights the difficulties in storing and transporting hydrogen as hydrogen liquefies at absolute zero (that’s minus 253c).

There’s another type of fuel derived from hydrogen: the colourless gas, ammonia. One common use for ammonia is fertilisers, but the use-case hopes stretch further. In September, the world’s first carbon-free ammonia-powered tugboat set sail along the Hudson River for the first time. Following the ‘does what it says on the tin’ naming protocol, the tugboat is called the ‘NH3 Kraken’ (NH3 is the formula for ammonia).

The technology is new but NH3 Kraken is old – she was originally built in 1957 and powered by diesel before being retrofitted into ammonia-powered. And other ships are expected to follow her lead.

“Several major ship engine makers are in the final stages of developing ammonia two-stroke engines for commercialisation by 2025… Ammonia is the primary low-emissions fuel used to decarbonise shipping, with the contributions from biofuels and hydrogen limited in large part by their relatively high costs.” IEA, Net Zero Roadmap

What makes ammonia a strong competitor to hydrogen?

At least three things…

- Ammonia liquefies at minus 33c, a much higher temperature than it takes to liquefy hydrogen – this means it requires less energy and is easier to liquefy than hydrogen.

- It is easier to store and transport.

- Existing transportation (think shipping and ports) and storage infrastructure for ammonia is already in place due to its long use as fertiliser. Ammonia is typically stored as a liquid in tanks or cylinders built to withstand the high pressure and low temperature requirements.

What’s happening around the world for ammonia?

- Planes! An Australian aviation company is planning the first ammonia-powered jet flight.

- Turbines! Japan is pushing the use of ammonia alongside hydrogen. IHI Corporation (IHI) is working with General Electric (GE) to develop gas turbines that burn 100% ammonia. Typically, hydrogen is compressed, liquefied or combined with nitrogen to create ammonia (for easy transport) then reconverted to hydrogen for combustion. In 2022, IHI fired the world’s first gas turbine using 100% ammonia by spraying liquid ammonia directly into the gas turbine combustor. IHI and GE are now on to the next phase of collaboration to develop a turbine combustor system that fires up to 100% ammonia in a safe and commercially competitive manner by 2030. This could eliminate the extra costs of converting ammonia back to hydrogen – a game-changer.

The use of ammonia as a green fuel has ignited some questions…

The most challenging issue, in simple terms to fellow non-scientists, is that the combustion of ammonia can generate nitrous oxide (NOx, a greenhouse gas). Treatments are needed to eliminate NOx emissions, and technical challenges remain.

“The industry’s current trajectory is unsustainable. Encouraging progress on near-zero-emission technologies is already being made. Near-zero-emission production methods are emerging, including electrolysis, methane pyrolysis and fossil-based routes with carbon capture and storage.” International Energy Agency, Ammonia Technology Roadmap

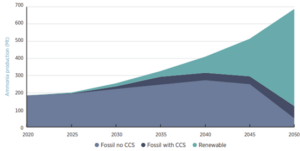

Ammonia contributes to roughly 1% of global CO2 emissions but there are promising predictions for a decarbonisation trajectory. The International Renewable Energy Agency (IRENA) has forecast a dramatic increase in renewable ammonia under the 1.5 degree scenario.

Source: IRENA, Innovation Outlook: Renewable Ammonia

Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO) has also flagged practical challenges: the high cost of producing renewable hydrogen (which is then converted to renewable ammonia) and safety.

“Ammonia is a toxic material, so careful regulation, training and engineering protections are required to keep the community safe. Ammonia has been in production for more than a century so none of these risks are new, but if we are going to produce a lot more ammonia and use it for new applications, then it’s important to make sure regulations and workforce training keep pace with the change.” CSIRO, Ammonia and Reaching Net Zero

Is ammonia cheaper and more efficient than hydrogen as a green fuel in the long run? Only time will tell. The green future is not a choice between hydrogen or ammonia but collective efforts.

Stay tuned for the next fun fact in this series – and subscribe to KWM Pulse for updates.

Want to know more about this clean fuel of the future?

You can read more from our experts worldwide on KWM’s Hydrogen page. To share your own favourite hydrogen fun fact, visit Scott’s LinkedIn page.

- Flying high with hydrogen – short-haul flights take off – King & Wood Mallesons Pulse (kwm.com)

- Buses, trucks and automobiles: The magical fuel cells and refuelling stations that are critical for hydrogen

- Whale of a shipment: The hope of the world’s first liquified hydrogen carrier

- Australia’s place in the hydrogen race

- Making crypto clean with hydrogen

- Challenge unsolved – hydrogen storage

- Saving money in hydrogen delivery

- South Korea’s ambitious hydrogen development

- IRENA’s treasure trove of green hydrogen fun facts